Fabricators, Inc is located in Chattanooga, Tennessee, the center of the popular southern industrial states. Main facility has 32,000 SQ FT building comprising different fabrication equipments as described below.

In addition, we also have a separate technological advanced fully automatic powder coating facility. It has 30,000 SQ FT building with lots of potential to grow in future.

Equipments:

1. Lasers:

3000 KW Cincinnati Lasers (Nos. 2).

Cutting capacity: ¾” Steel and 3/8” Stainless steel.

2. Press brakes

Amada CNC Press Brake, 100 Tons x 10' (Nos.2).

Nisshinbo CNC Press Brake, 125 Ton x 10', 8-Axis (Nos. 1).

Premier CNC Press Brake, 25 Tons x 4' (Nos. 2).

3. Robotic welding cell

ABB 1600ID 4 KG robot with IRC5 controller, FronuisTransPuls 4000 robotic welder and precision turn table installed with fixture plates.

4. Manual welding

Lincoln TIG Welder Square Wave TIG 255 (250A).

Lincoln TIG Welder Square Wave TIG 255 (250A).

Migmaster 250.

Migmaster 250.

Lincoln MIG Feeder.

Lincoln MIG Welder SP100 (100A).

Lincoln MIG Welder R3S-325 (325A).

Lincoln TIG Welder Square Wave TIG 275 (275A) w/ TigPulser.

5. Punches

Amada CNC Turret Punch Press, 30 Tons, 58 Stations, Auto Index.

Nisshinbo CNC Turret Punch Press, 33 Tons, 37 Stations, Auto Index.

Nisshinbo CNC Turret Punch Press, 25 Tons, 37 Stations, Auto Index.

6. Hardware installation and other miscellaneous equipments:

Pemster Pneumatic Hand Press, PEM inserter.

Pemsetter PEM Insertion Machine (Qty 2).

Pneumatic Riveter, 1/4" Dia.

Pneumatic Riveter, 1/8" Dia.

Tumbler, 1.5 hp, 44.5" long x 15.625" x 14.25" Tub.

Tumbler, 1.5 hp, 44.5" long x 15.625" x 14.25" Tub.

FMP Resistance Rocker Arm Spot Welder, 50kVA.

Kimura Rocker Arm Spot Welder, 30kVA.

AVK Pneumatic Swagging Tool.

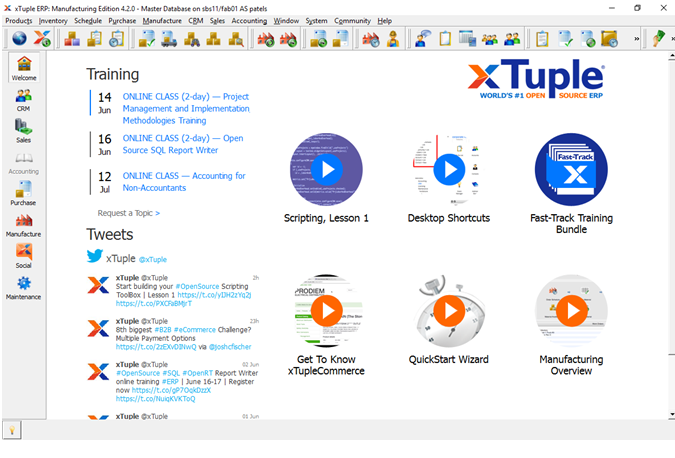

7. Enterprice resource planning software:

Manufacturing version of ERP with integrated platform to include different departments such as Sales, Purchasing, Manufacturing& Operations, Shipping, Accounting, Quality and Engineering

8. Powder coating Facility:

System Specification:

System Speed: 5 to 12 feet/minute.

Maximum Part Size: 10’ T x 9’ W x 10’ L.

System Performance: 2000 Hrs salt spray resistance.

Washer:

All stainless steel, 5 stage automatic pre-treatment system with ZERO discharge.

Interior Size: 12’ T x 10’ W x 64’ L.

Process cycle time per stage: Up to 90 seconds.

Pretreatment Chemistry: Zirconium Based with sealant.

Dry-off Oven:

Burners - Natural gas operated.

Two burners with 1.5 Million BTU each.

Interior Size: 10’ T x 10’ W x 40’ L.

Dry time: Minimum 8 minutes at 400 deg F at 8 feet per minutespeed.

Powder coating spray booth:

Burners - Natural gas operated.

Interior Size: 10’ T x 10’ W x 40’ L.

Dry time: Minimum 8 minutes at 400 deg F at 8 feet per minute speed.

Powder Curing Oven:

Burners - Natural gas operated.

Four burners with 1.5 Million BTU each.

Interior Size: 10’ T x 40’ W x 47’ L.

Curing Cycle: Minimum 20 minutes at 400 deg F at 8 feet per hour speed.